Discover the advanced technology that powers the future of observation

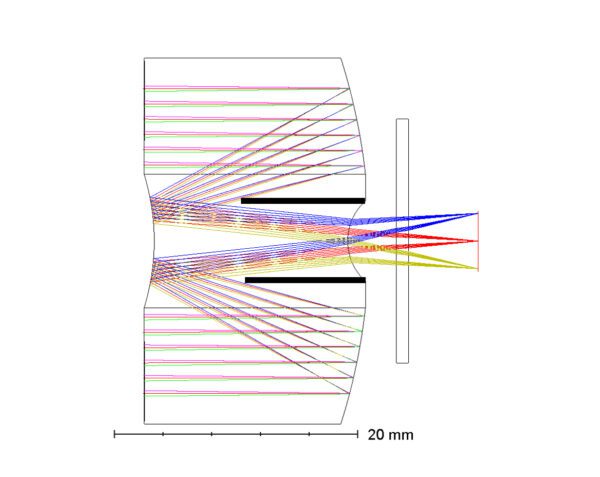

A Tiny Telescope contains several optical functions in a single piece of fused silica. The main telescope functionality is provided by two reflective mirrors. The first mirror is called the primary mirror and focuses the captured light onto the secondary mirror, that creates a more condensed beam of light. In the Tiny Telescope these reflections happen inside the glass itself. Additional optics are needed to provide a well corrected image. The first surface is a transmissive surface to ensure that all optical rays meet in the same focus. The last surface is a transmissive surface to ensure that the image is flat and can be observed by a CCD, capable to capture the image electronically. Absorbing features called baffles are created in the glass of the Tiny Telescope, in order to avoid that spurious rays of light reach the CCD and could destroy the image.

Tiny Telescope features an advanced optical system that utilizes both refractive and reflective surfaces in a single optical component. Aspherical surfaces achieve unparalleled field control and image sharpness. This design minimizes aberrations, ensuring crisp, clear images across the entire field of view.

Constructed from the highest quality materials, Tiny Telescope is engineered to withstand extreme conditions. Its temperature-insensitive design and robust build ensure consistent performance whether you’re observing in the arctic cold or the sweltering heat. The lightweight design also makes it incredibly portable without sacrificing durability.

Unlike traditional telescopes that require meticulous alignment of individual lenses, which are prone to drift, Tiny Telescope offers a no-alignment, no-drift solution. Its diffraction-limited optics provide sharp, high-resolution images free from common distortions such as diffraction spikes. Moreover, Tiny Telescope’s maintenance-free design ensures that it stays ready for action with minimal upkeep, making it both a reliable and cost-effective choice.

The first Tiny Telescopes have been created in the mid 1990’s, and are based on the molds that are used to produce cataract replacement lenses. Back then manufacturing was all done by hand with a lot of trail and error. It could take over a year to manufacture a single Tiny Telescope. This was a costly endeavor and there were few applications in the time before internet, cell phones and CCD’s became mainstream. .

In 1994, the first prototype featuring a curved primary mirror was developed. This early innovation marked a significant step towards creating a compact yet powerful optical system, laying the groundwork for the future of Tiny Telescope.

Fast forward to 2020’s: social media are thriving and people constantly have their cell phones withing reach, offering multiple cameras and broadband internet connectivity. Automated manufacturing of high quality optics is possible in large quantities and becomes affordable. Even the stringent specifications of a Tiny Telescope can be achieved. Soon drones will be used for automated inspections and laser satellite communication networks offer even higher data rates and global coverage.

In 2024, Tiny Telescope was perfected for use in satellite applications, offering unprecedented performance in a small, portable form factor. This marked the transition from concept to reality, with Tiny Telescope being ready for mass production and integration into various market applications.

As we look to the future, Tiny Telescope continues to evolve. Upcoming developments include further miniaturization, enhanced integration with digital systems, and expanding its capabilities across new wavelengths and applications. Stay tuned as we continue to push the boundaries of what’s possible in optical technology.

| Tiny Telescope | Traditional Telescope | |

|---|---|---|

| Size and Portability | Compact and lightweight, easy to transport. | Bulky, often requires a stationary setup. |

| Optical Performance | Diffraction-limited optics, sharp images. | Requires alignment, prone to drift. |

| Durability | Robust, designed for harsh environments. | Sensitive to conditions, requires maintenance. |

| Cost Efficiency | High performance at a lower cost. | Typically more expensive with higher maintenance costs. |

The optical surface in the Tiny Telescope contain several aspherical surfaces in order to improve the optical performance. In normal optics such aspherical surfaces are already hard to manufacture with nanometer accuracy, the size of only a few atoms. Since the reflections in the Tiny Telescope happen inside the glass, a surface inaccuracy of 1nm will result in an optical error of 3nm. This is 6 times worse that for a transmissive surface, meaning that the manufacturing accuracy of the shape of the optical surfaces in the Tiny Telescope must meet extremely tight specifications. Another key element is that all 4 optical components have to be manufactured with enormous position accuracy with respect to each other, as there is no option to align one surface with respect to another surface after manufacturing. Finally the baffles with absorbing coatings have to be manufactured inside the glass with great care, in order to avoid affecting the refractive index of the glass itself.

If you’re interested in the Tiny Telescope and want to find out more details, this is the place to be. Below you can find some links to popular and professional publications. Better yet: contact us and let’s find out what Tiny Telescope can do for your business.